Texas Instruments secures its ability to meet global demand and control its supply chain with a dedicated effort to design and manufacture its innovative products at several sites around the world.

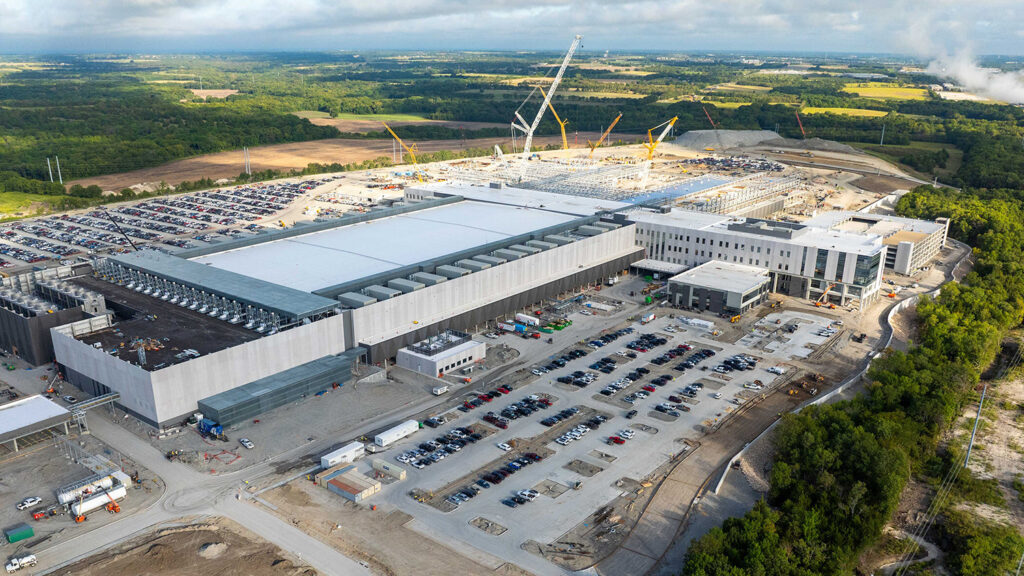

In particular, TI is expanding its global manufacturing footprint with strategic investments in 300mm wafer fabrication plants, known as fabs. IWR served as the building enclosure partner for TI’s wafer fabs in Sherman, Texas — one of the largest private-sector investments in the state’s history, and a technically challenging project demanding a high-performance enclosure system.

TI expects the highest level of craftsmanship and technical innovation for its projects. For example, its 300mm factories are designed to meet LEED Gold standards and will be powered by 100% renewable electricity. This requires trusted partners who can meet the scale, schedule and precision required to manufacture millions of electronic chips daily.

For the first of the four fab plants, SM1, IWR delivered a high-performance enclosure system, essential for protecting the facility and supporting its operations, using insulated wall panels, corrugated wall panels and louvers.

“Our work was integral to the startup of the building,” Brandon Klein, IWR Senior Project Manager, said. “The electrical room being enclosed with insulated wall panels essentially formed the face of the building, including the visible finish as well as the waterproofing layer. IWR’s role in this project impacted both the aesthetic appearance and the building’s critical first line of defense against water.”

Spanning more than 117,000 square feet of a variety of insulated panels, single skin and louvers, the project demanded airtight planning, meticulous installation and adaptive fieldwork. IWR’s self-performing crew, consisting of a talented Dallas-based union workforce, managed procurement logistics across a mile-long site and planned for unexpected circumstances. For example, ordering materials ahead of time helped IWR maintain a rigorous schedule with little overtime.

Much of IWR’s enclosure work is hidden within the structure in areas like the scrubber deck and cooling tower walls and plays a vital role in maintaining a clean and controlled manufacturing environment.

“Waterproofing for a manufacturing facility is essential, so IWR took meticulous care with the materials on this project,” Brandon said. “There were more than 500 wall penetrations on the project that we had to make watertight. The true test came when it rained and our panels held tight without a single leak. This speaks to our field crew’s expertise in protecting buildings from the elements.”

The TI Sherman fab stands as a prime example of the IWR way when it comes to planning, expertise and building long-lasting, weather-resistant enclosures.

Testimonial from Austin Commercial

“Working with IWR contractors was a truly positive experience. Brandon, Keleigh, and the team were not only honest and reliable but also proactive and highly collaborative. They came prepared, stayed ahead of coordination items, and worked seamlessly with our project team to keep everything moving smoothly.

What truly set them apart was their foresight and problem-solving approach. Instead of reacting to issues, they anticipated challenges early and partnered with Austin to deliver practical, economical solutions that kept the project on schedule. Their commitment and professionalism made them feel like true partners—not just another contractor.”

“Waterproofing for a manufacturing facility is essential, so IWR took meticulous care with the materials on this project,” Brandon said. “There were more than 500 wall penetrations on the project that we had to make watertight. The true test came when it rained and our panels held tight without a single leak. This speaks to our field crew’s expertise in protecting buildings from the elements.”